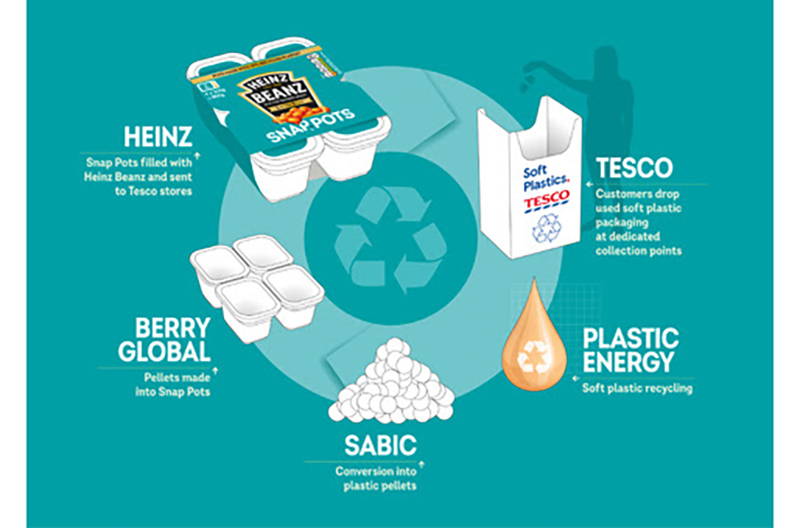

SABIC has joined forces with Heinz, Tesco and Berry in a recycling trial in the U.K. designed to close the loop on soft plastic food packaging.

Flexible plastic packaging collected from Tesco stores has been used to produce certified circular polypropylene from SABIC’s Trucircle portfolio for microwavable Heinz Beanz Snap Pots, made from 39 percent recycled soft plastic.

The transformation of the industry toward a circular economy requires collaboration across the value chain. This achievement is another example of its commitment to accelerate the change and ensure that plastic products are designed, produced, used and recycled more sustainably.

Consumers are encouraged to return soft plastic packaging to collection points set up at Tesco stores. A portion of this collected plastic packaging is converted into recycled oils, called TACOIL, through a thermal anaerobic conversion process. SABIC uses the oil to produce certified circular polypropylene of the same quality as virgin resin.

With these polymer pellets, Berry Global manufactures the new Beanz Snap Pots and sends them to Heinz for filling with Beanz and delivery to Tesco. Once emptied, the pots and sleeves can be returned to curbside collection points.

The collaboration aligns with SABIC’s Trucircle program and the company’s commitment to drive the transformation of the plastic packaging economy towards circularity. “We are happy to reaffirm our role as a provider of unique circular solutions,” said Lada Kurelec, general manager PP, PET, PS, PVC, PU and elastomers businesses for petrochemicals at SABIC.

“Next to the material know-how, we have brought value chain partners together and provided crucial elements such as support with certification processes or life-cycle assessment calculations, all while helping to prevent valuable used plastics from being lost to landfill or incineration.”

The Snap Pots recycling trial is part of Heinz’s global pledge aimed at making 100 percent of its packaging recyclable, reusable or compostable by 2025.

“We’re proud to have teamed up with experts in the field of advanced recycling and sustainable packaging to bring this important innovation to our customers,” said Jojo de Noronha, president Northern Europe at Heinz. “Our hope is that this prompts an industry-wide look at what more can be done to address the lack of soft plastics being recycled in the UK, and we can, as a collective, get better when it comes to developing new packaging solutions that are both good for both our consumers and for our planet.”

To date flexible packaging has been difficult to recycle, and until 2020 just 6 percent of soft plastic packaging was being recycled in the UK. Tesco started collecting soft plastic in all its large stores in 2021 to help plug this recycling gap in the UK. The Heinz and Tesco project with certified circular polymer from SABIC is considered a breakthrough with the potential of a real game changer.

The new Heinz Beanz microwavable pots are made with 39 percent of certified circular SABIC PP homopolymer suitable for injection molded or thermoformed food packaging products.

The material meets the requirements of food-contact safety regulations and will replace virgin PP in a thin-wall application without compromising processability or mechanical performance. The recycled content in the Snap Pots is validated by mass balance according to the International Sustainability and Carbon Certification PLUS program.

For more information, visit ff.sabic.eu/en/sustainability/trucircle-portfolio.